THE SANCO2 HEAT PUMP WATER HEATER IS REVOLUTIONIZING THE INDUSTRY.

Find out why the SANCO2 was named a

HOMEOWNERS ENJOY

-

A better supply of hot water

-

Low environmental impact

-

Lower monthly utility bills

-

Whisper quiet operation

-

Cool climate performance

SANCO2 Heat Pump Water Heater

Sanden is using CO2 or R744 as the refrigerant in our Heat Pump Water Heater to increase both performance and efficiency, in addition to protecting the environment. We take advantage of the Supercritical and Transcritical natures of the CO2 refrigerant for heating water.

Above a temperature of 31 oC or 88 oF CO2 can be described as being Supercritical. The term we use to describe the Heat Pump Water Heating process is Transcritical, as the CO2 is moved across the boundaries of its fluid state. Supercritical status allows CO2 to behave in a different manner than that expected from a fluid or gas in the sub critical range.

A supercritical fluid has properties basically between that of a gas and a liquid, where it expands to fill a container (or heat exchanger in this case) like a gas, but it’s density is essentially that of a liquid, which helps increase the potential for very efficient (rapid) heat exchange between the supercritical fluid and the water to be heated. This enables the Sanden SANCO₂ unit to rapidly raise the incoming cold potable water to our target temperature of 149°F (65°C) for delivery back to the storage tank.

- For a Transcritical CO2 cycle, the cycle crosses the boundaries between critical and supercritical states.

- The heat being absorbed at the evaporator takes place below the critical pressure of 7.1 MPa or 1030 Psig.

- The release of heat within the gas cooler (Condenser) takes place above the critical pressure and temperature of 1030 Psig (7.1 MPa) and 88°F (31°C)

Due to this, heat is released over a temperature range. This is in contrast with conventional compressor systems where heat release takes place at a fixed temperature. (Traditional Condensing Temperature). Therefore we talk about a gas cooler instead of a condenser; the CO₂ refrigerant will not condensate, it is only cooled.

Introducing

North America’s first eco-friendly

CO2 hot water solution

Components

A system based on the transcritical CO₂ cycle needs to use a specific type of High Pressure Expansion Valve, controlled electronically.

- The Expansion Valve controls the flow of CO₂ from the Gas Cooler, unlike a normal thermostatic or electronic expansion valve it does not reference evaporator or suction superheat to refrigerant flow.

- The Expansion Valve uses increases or decreases in Gas Cooler pressure to control refrigerant flow in the system. The control of the valve and hence the CO₂ flow rate in the Sanden system is controlled electronically by the unit, to optimize the efficiency and performance of the system.

- System superheat becomes a function of the charge distribution and compressor capacity control to ensure that any liquid CO₂ refrigerant at the evaporator outlet does not return to the compressor.

- Unlike a traditional HVAC system or Synthetic Refrigerant Heat Pump Water Heater, the Sanden unit does not look to the Evaporator design and control as the main driver for performance.

- The control of the CO₂ flow and pressure in the Gas Cooler is the main driver on system performance and efficiency.

- Therefore one of the major contributors to system efficiency is the cold water temperature to the inlet of the gas cooler.

Conventional wisdom determines that all Water Heaters including synthetic refrigerant HPWH’s have better performance with warmer inlet water conditions, however this is not the case with the Sanden SANCO₂ HPWH as lower inlet water temperatures allow the Gas Cooler to operate at maximum efficiency and performance.

This operation is only possible because of our ability to harness the very specific properties of Transcritical CO₂ as the refrigerant in the system.

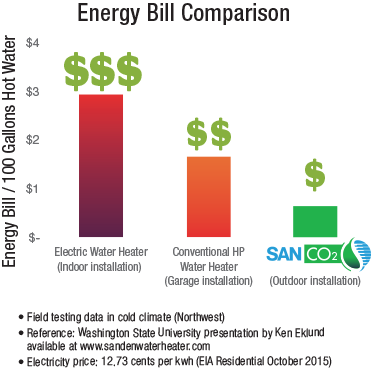

ULTRA HIGH EFFICIENCY REDUCES ENERGY BILLS: USES OVER 70% LESS ELECTRICITY

The SANCO2 system uses an inverter-type compressor, DC fan motor and pump. Our design minimizes energy consumption, maximizes water-heating capacity, and allows for faster recovery, resulting in significantly lower operating costs than electric-resistance storage water heaters or conventional heat pump water heaters.

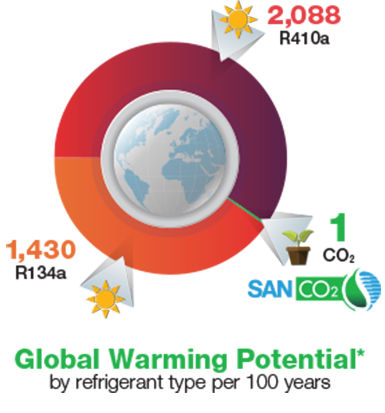

MINIMAL IMPACT ON GLOBAL WARMING: UNIQUE OZONE-FRIENDLY CO2 REFRIGERANT

Heat pump water heaters commonly use synthetic refrigerants, such as R410A or R134A. Although these refrigerants do not deplete the ozone layer, they can have a significant impact on global warming. The CO2 refrigerant uniquely used in the SANCO2 system has an extremely low Global Warming Potential*, and CO2, a natural refrigerant, does not deplete the ozone layer.

LOW PROFILE DESIGN

- Whisper-quiet noise level (38dB)

- Slimline heat pump design for a reduced footprint

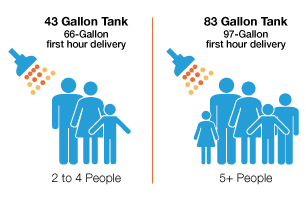

HIGH PERFORMANCE

- Greater first hour rating than all heat pump water heaters

- Faster recovery after hot water draw

- Two sizes to best fit your hot water needs

EXTENDED OPERATING RANGE

- Hot water production down to -15°F

- 149°F delivered hot water temperature

- No need for a back up electric element in the storage tank

EASY INSTALLATION: FLEXIBLE 2-PIECE SYSTEM

The tank is installed indoors and the heat pump outdoors (up to 25 feet away) with only water piping connections required between the two.

This flexible SANCO2 design offers several advantages including maintaining comfortable indoor air temperatures (unlike conventional heat pump water heaters that ’scavenge’ heat from the indoor air), along with reducing in-home noise.

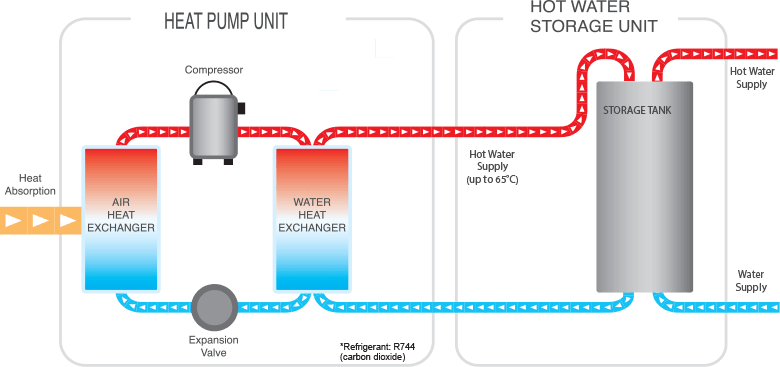

EFFICIENT OPERATION: HOW THE SANDEN SANCO2 SYSTEM WORKS

A heat pump uses a small amount of energy to move heat from one location to another. In the SANCO2 system heat in the air is absorbed by a natural refrigerant, CO2, which is ozone friendly and does not contribute to global warming.

The warm gaseous refrigerant is circulated in the system via a compressor. As it passes through the compressor, its pressure rises, as does its temperature. This hot refrigerant then passes through a heat exchanger to heat the water, which is then pumped to the storage tank.

Advantages of the Sanden SANCO₂ transcritical CO2 Heat Pump Water Heater

- Provides a large temperature rise (at least 70-100 °F, 39-56°C) in the DHW heated in the Gas Cooler.

- With a low incoming water temperature at the inlet of the Gas Cooler, the efficiency of a CO2 transcritical heat pump is much higher than conventional heat pumps, a COP of > 5 can be achieved

- This is why CO2 refrigerant is ideally suited to HPWH applications, typically the City Water temperatures entering the Gas Cooler are below 50°F (10°C) and this actually works to increase the efficiency of a SANCO2, demanding a large temperature rise, in contrast, decreases the efficiency of synthetic refrigerant HPWH units.

- Operation in ambient temperatures below freezing, because the Evaporator is not the driver in system efficiency the Sanden SANCO₂ HPWH can still provide 149°F (65°C) water in temperatures as cold as -13°F (-25°C) ambient – The COP at that ambient temperature is still > 1.0

- CO₂ is a low GWP refrigerant, with a GWP of 1, it is a natural substance and hence environmentally friendly

Disadvantages of the Sanden SANCO₂ transcritical CO2 Heat Pump Water Heater

- The temperature of the water that needs to be heated has to be low enough for the heat pump to achieve a high coefficient of performance (COP). If the CO2 is not cooled enough by the water flowing in, the process will not be as efficient as it could be.

- The system has to work in the supercritical range, requiring a high side pressure greater than 1030 Psig (7.1 MPa). Hence the SANCO2 unit is a split system with the CO₂ refrigerant factory charged and sealed in the Outdoor unit, and water at pressures below 75 Psi (520 kPa), typical City Water Pressure is pumped in and out of the Outdoor Heat Pump unit

Warranty – Best in Water Heater Industry

- First three years parts & labor on compressor unit and tank.

- First three years replacement of compressor unit for failure of water or refrigerant heat exchanger, compressor or refrigerant part.

- At the end of the first three years this three year replacement and labor warranty may be re-purchased for $200 CDN

- Beyond the first three years of free parts and labor, the compressor unit has a ten year parts warranty, and the tank has a 10 year parts warranty with declining coverage in years 11 through 15:

- After 11 years the tank is warrantied at 80% of original value

- After 12 years the tank is warrantied at 60% of original value

- After 13 years the tank is warrantied at 40% of original value

- After 14 years the tank is warrantied at 20% of original value

- After 15 years the tank is out of warranty

Sanden is a global leader in heat pump innovation, you are encouraged to view the videos below

You can learn more about Sanden company at: www.sandenwaterheater.com